Portable & Stationary Silos for Concrete Batch Plants

Concrete Batch Plant Equipment >> Silos

Custom Manufactured Batch Plant Silos Available Nationwide

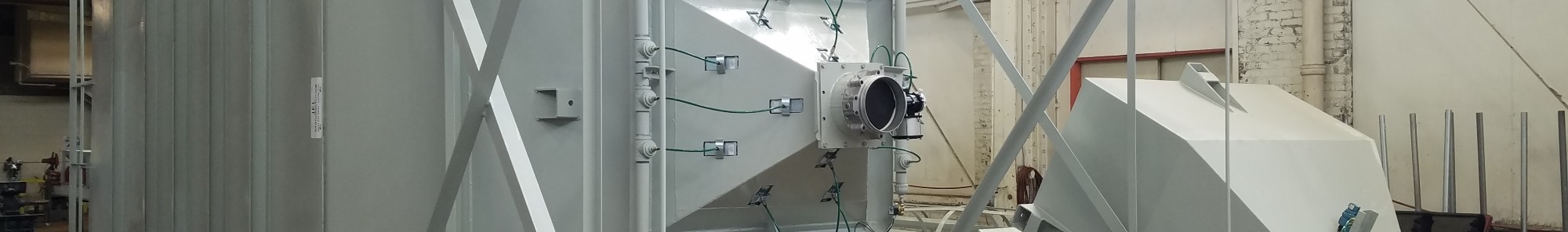

Through our partner company, Fesco Direct, JEL Concrete Plants sources both stationary and portable silos for small to mid-sized operations. All silos are custom-designed to your specifications and manufactured in the Milwaukee area by experienced metalworkers. See our RIO Calculator for pricing.

GET A FREE QUOTE

Concrete Plant Silos for Small to Mid-sized Operations

Concrete plant silos serve as integral components in the batching process, facilitating the efficient storage and dispensing of key materials such as cement, fly ash and aggregates. Our bulk batching plant silos are meticulously designed in the Milwaukee area to cater to the specific needs of your operations. Our batching plant silos are built to withstand the demands of consistent and heavy-duty use within the concrete industry. Their compact design ensures efficient utilization of space while maintaining seamless material flow, enhancing the overall batching process.

Features and Benefits of Batching Plant Silos

The features and benefits of our batching plant silos make them indispensable assets in concrete production. Concrete plant silos are equipped with mechanisms such as dust collectors and aeration systems which ensure the quality of stored materials while adhering to environmental standards. The design enables easy monitoring and maintenance, further streamlining operations. By preventing material segregation and ensuring consistent flow, concrete plant silos contribute to the production of high-quality concrete. Additionally, the containment of materials within silos minimizes waste, enhancing the cost-effectiveness of your operations.