All standard models support deep customization to maximize production efficiency while controlling upfront investment.

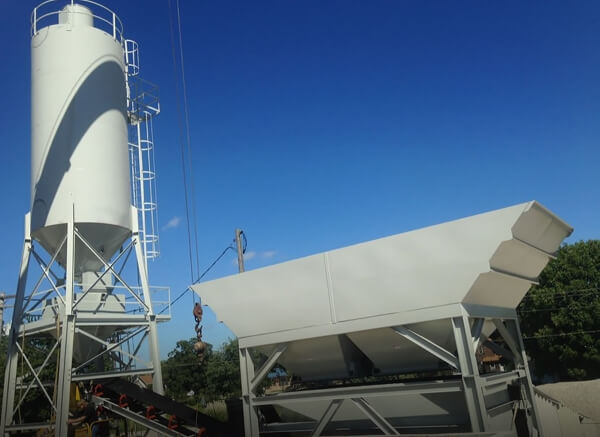

Free QuoteReady Mix Concrete Batch Plants for Sale

Custom RMC Batch Plants Designed, Engineered & Manufactured in the USA

JEL designs and builds ready mix concrete batch plants for producers across the United States. Each plant supports scalable production and extensive customization to match site conditions, material handling needs and long-term growth plans. All systems are designed, engineered and manufactured in the USA using locally sourced, high-strength steel and factory-supported components. Reach out to request pricing or discuss a custom configuration.

Three Core RMC Plant Models, Configurable for Dry (Transit) or Wet (Central) Mix

JEL offers three core ready mix concrete batch plant models, each engineered for specific production demands and budget ranges. Every model supports dry mix or wet mix configurations, allowing producers to align plant design with delivery methods, mix requirements and output goals.

The Decumulator®

A high-production, versatile batching system built for demanding operations requiring speed, consistency and flexible layouts.

The Acumulator™

A fully customizable batching plant suited for producers seeking scalable output and long-term expansion potential.

BudgetBatch™

A cost-conscious batching solution designed for low production needs, satellite plants or phased growth strategies.

Plant Type Configurations & Applications

JEL designs ready mix batch plants to support a wide range of production methods and jobsite requirements.

Dry Mix (Transit Mix) Batch Plants

Dry mix plants load cement, aggregate and admixtures into transit trucks without adding water at the plant. Mixing occurs during transport, offering flexible delivery timing and lower initial investment.

Wet Mix (Central Mix) Batch Plants

Wet mix plants combine all materials, including water at the plant before discharge. Central mix configurations support faster cycle times and consistent mix quality for high-spec or high-volume applications.

Mobile & Compact RMC Plants

Portable and compact systems support on-site production, remote projects and space-constrained locations. JEL designs both dry and wet mix mobile configurations for infrastructure, commercial and specialty applications.

Custom Design & Build Process

JEL works closely with concrete producers to design batching plants matched to specific production targets, site layouts and operational workflows. From initial planning through installation, each system reflects practical production requirements and future expansion plans. Options range from compact mobile plants to high-output stationary systems with advanced automation and material handling features>

Cost Planning & ROI

JEL supports cost planning through an ROI-focused approach to plant design. Modular engineering and upgrade-ready frameworks allow producers to start with a right-sized system and expand later as demand increases. Automation options, material handling layouts and production capacity all factor into long-term operating value.

Producers can use JEL’s ready mix batch plant ROI calculator to estimate costs and plan a custom build aligned with production goals.

Why Choose JEL?

JEL batch plants are built in the USA using locally sourced steel and factory-supported components, delivering durability, performance and long-term value. Lean design and manufacturing practices help control costs while maintaining build quality. With decades of experience and nationwide support, JEL serves as a trusted partner for scalable and reliable, ready mix concrete batching solutions.

Custom RMC Batch Plants Available Nationwide

JEL manufactures ready mix batch plants for concrete producers across the United States, including those in Philadelphia, Los Angeles, San Antonio, Houston, Dallas, Phoenix, Seattle, Denver, Chicago, Atlanta, Wisconsin, Iowa, Illinois, Michigan, New York, New Jersey, Pennsylvania, North Carolina, Georgia, Florida, Texas, Colorado, California, Washington and beyond.

Central Mix Concrete Batching Plants

JEL designs high-performance central mix concrete batch plants for both stationary and portable applications. Whether you need a permanent installation for ready mix production or a mobile setup for large-scale projects, we custom-build systems to fit your site layout and logistics. Our trailer-mounted options ensure fast transport and simplified on-site setup.

Precast Concrete Batching Plants

JEL manufactures precast concrete batching plants in Wisconsin using durable, U.S.-sourced steel and components. We offer fully customizable solutions built to match your production volume and mixer preferences, with planetary mixers ranging from ⅓ to 5 cubic yards and twin-shaft mixers up to 12 cubic yards. Whether you need a high-output or compact Decumulator setup, we’ll design a precast plant tailored to your specific requirements.

GET A FREE QUOTE ...or calculate the cost of your ready mix concrete batch plant with an ROI estimate.

For a new ready mix concrete plant system – contact FESCO Direct

FESCO Direct is our partner in sourcing and distributing ready mix dry batch concrete batch plants for sale. If you’re looking to build a new system, get in touch with them and they’ll coordinate all equipment manufacturers to facilitate construction.

Ready Mix Concrete Batch Plant FAQs

What is the difference between dry mix and wet mix batch plants?

Dry mix plants load materials without water, allowing mixing during transport. Wet mix plants combine all ingredients at the plant, producing a consistent mix before loading.

How much does a ready mix concrete batch plant cost?

Cost varies based on production capacity, configuration, automation level and mobility. JEL offers scalable options designed to match different budgets and operational needs.

Can a ready mix batch plant be expanded later?

Yes. JEL batch plants support future upgrades like added silos, increased hopper capacity and expanded automation as production demands grow.